“Rapid Foam Knockdown. Enhanced Process Throughput. Maximum Yield.”

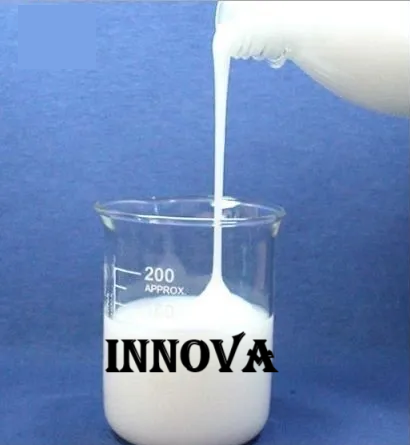

Innovacorp India provides a comprehensive range of Defoamers and Antifoaming Agents specifically formulated to handle the intense foaming challenges in sugar manufacturing and fermentation. Excessive foam disrupts juice clarification, evaporation, and distillation, leading to sugar loss and reduced plant capacity. Our advanced chemical solutions provide immediate foam collapse and long-lasting suppression, ensuring smooth, hygienic, and efficient operations.

Our Industrial Defoamers are engineered using high-grade silicone-based, mineral oil-based, and ester-based active agents. These formulations are designed to maintain stability even under the high-temperature and high-alkalinity conditions typically found in sugar juice evaporators and distillery fermenters.

Produced at our state-of-the-art GIDC Dahej facility, Innovacorp’s Defoaming Agents are field-tested for the most difficult foaming media. We offer tailor-made silicone and non-silicone variants backed by technical support to help you choose the right product for your specific process chemistry.

Conclusion:

Innovacorp Defoamers are an essential tool for maintaining high productivity in

modern sugar mills and distilleries. By ensuring foam-free processing, we help you achieve

consistent quality, reduced operational costs, and optimized plant efficiency. Eliminate process

bottlenecks with Innovacorp’s expert foam control technology.

© 2026 Innovacorp India Pvt Ltd. All Rights Reserved. Managed & Developed by Innova Corporate India